Engineers solve problems every day. I have been practicing the Mechanical Engineering profession for over 10 years and every day I solve problems. Every big problem can be broken down in small bits, which become a problem to solve on their own. Like in any profession, one very important step to solve a problem is to find the right tool to get the job done in the most effective and efficient way. In the digital age, most of these tool that I am talking about end up being some type of computer software. I often find myself mentally evaluating different software packages against the details of the problem at hand. For this reason, I have tried here to provide a decision tree style flow chart to illustrate the typical thinking process used by many mechanical engineers to choose the right software for the job.

ME Software Flow Chart

CTX gamma 2000 TC

Here is a fun video to watch that shows how far we’ve come with CNC machining.

Well done!

ForceEffect for Android

A while back I wrote a post about an app called ForceEffect by Autodesk. This very useful app is now available for android on Google Play. Give it a try and see what you think. If you find it useful, also check out ForceEffect Motion.

Keep up the good work Autodesk!

Curiosity’s Landing on Mars

After a journey of over eight months, Curiosity is scheduled to land on Mars this Sunday, August 5th at 10:31 pm PDT. Check out this video that explains how exciting, challenging, and complex this landing will be. All I can tell you is that the 7 minutes that it takes to get from the top of the atmosphere to the surface of Mars are being described as the 7 minutes of Terror. When will we know if we made it to the surface safely or not? It will take 14 minutes for a communication signal to travel from Mars back to Earth!

It might look like science fiction but it truly is just real science and engineering

EveryCircuit on Google Play

Here is a very useful android app for designing and simulating electronic circuits. This app provides a dynamic animation of voltage, current, and charge which makes the design of electronic circuits easy, intuitive, and fun! Take a look and see what you think.

edX: An MIT and Harvard Partnership

Free online classes from MIT and Harvard. Doesn’t get much better than that! I encourage all of you to take advantage of this new resource. As a current MITx student enrolled in 6.002x, I can tell you first hand that these online education opportunities will eliminate geographical and socio-economical boundaries for education and will revolutionize they way we all learn.

Conjugate Heat Transfer With COMSOL Multiphysics

Take advantage of this FREE webinar which explores heat transfer analysis in combined fluid and solid systems (conjugate heat transfer) using COMSOL multiphysics.

The webinar is offered on March 28, 2012. Sign up today!

ForceEffect By Autodesk

Here is another great app for your Iphone, Ipod Touch, or Ipad. ForceEffect is a FREE application developed by Autodesk that performs static force calculations (Yes, free-body-diagrams included).

This application is great for engineers at all levels (and architects too!). A static problem carried out by hand can take a significant amount of time. For instance, look at the following example:

While the same problem can be solved using ForceEffect in seconds, check it out:

It even gives you a report with the result summary:

Great app, I highly recommend it, good for checking your homework and brainstorming ideas for new design concepts.

3-D Numerical Study of the Effect of Thermocouple Normal Distance Location on the Steady State Surface Temperature of a Cylindrical Test Section

A 3-D thermal finite element analysis (FEA) was performed through ANSYS on a cylindrical test section. The model included 4 holes parallel to the top flat surface of the cylinder, each at different radial depths. The holes represented thermocouple locations that can be used to measure the radial surface temperature distribution of the test section.

The top of the test section was modeled with a constant convective boundary condition of 6000 W/m2-K while the bottom surface had a uniform heat flux boundary condition of 100 W/cm2 . All other surfaces were insulated. Other Dimensions: D= 27.64 mm, DT =1.6 mm, H=32 mm

The objective was to find the minimum distance from the surface to the thermocouple holes (L) that would eliminate the effect of the thermocouple presence on the top surface temperature distribution. To ensure that top surface temperature variations are not caused by the thermocouples, the thermocouples should be located at a distance below the surface (L) that results in top surface isothermal conditions when exposed to a constant convective heat transfer coefficient.

Results show that for stainless steal, the thermocouples should be located at a distance greater than L=12DT for the thermocouples not to significantly interfere with the top surface temperature distribution

One way of keeping the thermocouples closer to the surface without interfering with the surface temperature distribution is to make the test section out of a higher thermal conductivity material. Results show that as the thermal conductivity of the material increases,the surface temperature distribution is less affected by the presence of the thermocouples.

Part Drawings

After creating a 3-dimensional design in CAD software such as SolidWorks, Pro/Engineer, AutoCAD, CATIA, and so on, it is almost always necessary to create a part drawing of the model before machining it. A part drawing is a 2-dimensional representation of the 3-dimensional part which contains all necessary information required to build the part in a machine shop. Required information includes material type, units, dimensions, tolerances, scale, part name and all necessary views of the part which could also include cut-out section views. The part drawing should be prepared in such a way that a machinist should be able to precisely machine out the part just by looking at the information provided in it. Most CAD software have a feature to create a 2-dimensional part drawing from a 3-dimensional model. However, it is the engineer responsibility to make sure that the part drawing is accurate, clean and complete. Lack of information would make the part impossible to build based on the drawing itself, while too much information can make the part drawing difficult to read. Even though Computer Numerical Control (CNC) machine tools are revolutionizing the machining industry, 2-dimensional part drawings are still largely used and very important. The part drawing is the major mean of communication between the design engineer and the machinist regardless of the machining process being used. Here are a couple of examples of part drawings that I have made using SolidWorks and were machined successfully.

Electrical Circuits

Surfboard in CAD

Computer-aided Design

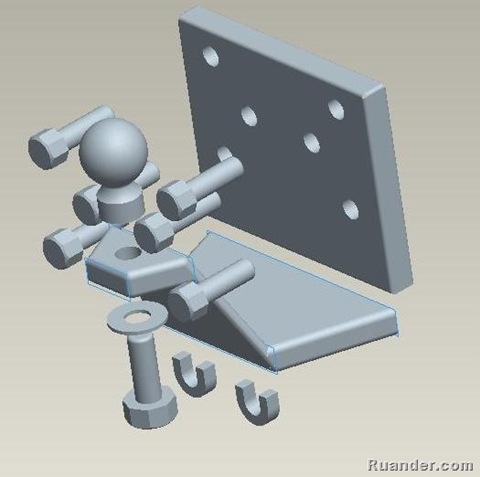

Although the design process should start with a blank sheet of paper and a pencil, and should end with a working product, the use of CAD products in between these two design stages is nowadays crucial to ensure the success of the any project no matter what the scale of the project is.

Several CAD software are available. Getting familiar with one usually requires practice. Above are some pictures of a trailer hitch for a Jeep CJ-5 that I modeled with the aid of Pro-E (while practicing). I copied (and modified) the design from my Dad’s Jeep (below).

By the way, visualizing the CAD model and analyzing a little bit I already see many areas of improvement in this particular design.